01

High Performance POF Shrink Film

Product description

High Performance POF Shrink Film is a cutting-edge packaging solution designed to meet the stringent requirements of various industries. Crafted from premium polyolefin material, this film offers exceptional performance and delivers accountable results in a wide range of applications.

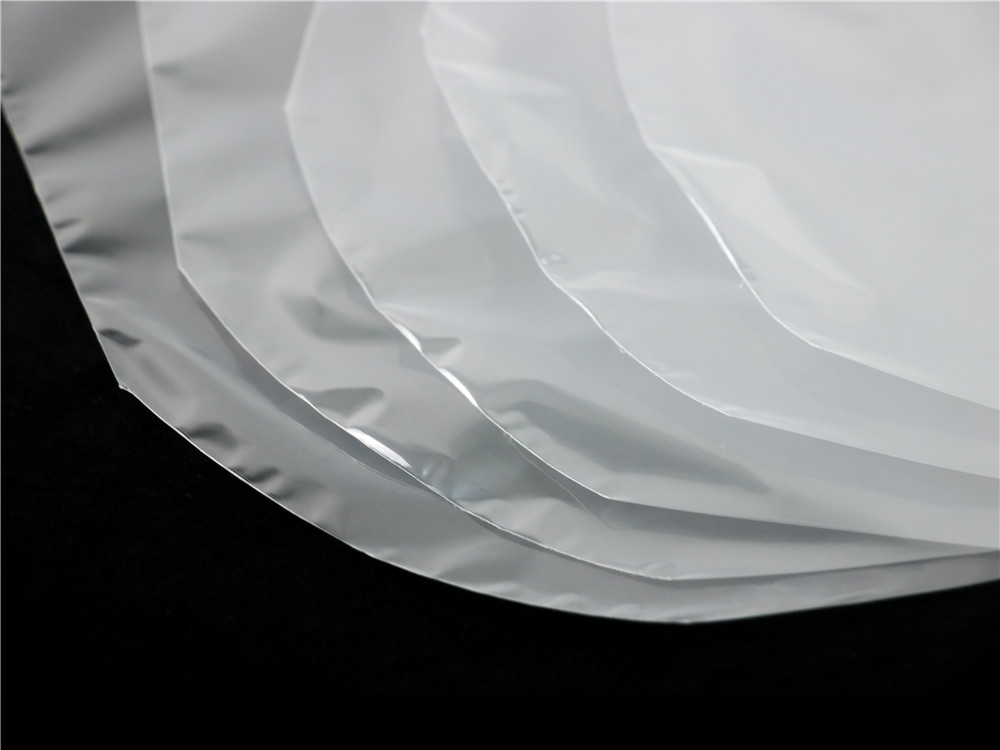

Flexibile Wrapping

One of the key features of High Performance POF Shrink Film is its remarkable flexibility. This film can be easily shaped and molded to accommodate diverse packaging needs, making it a multiple choice for various products.

High Strength and Durable

High Performance POF Shrink Film is renowned for its exceptional strength and durability.

In addition to its outstanding physical properties, High Performance POF Shrink Film also meets the highest industry standards for safety and hygiene. It is widely used in the food and beverage industry, where strict packaging requirements are essential to preserve product integrity. This film is non-toxic, odorless, and free from any harmful substances, making it a reliable choice for packaging.

High performance POF shrink film is an exquisite shrink product designed for customers who require high and specific shrinkage rates in certain implicit parts of the film shrinking process.

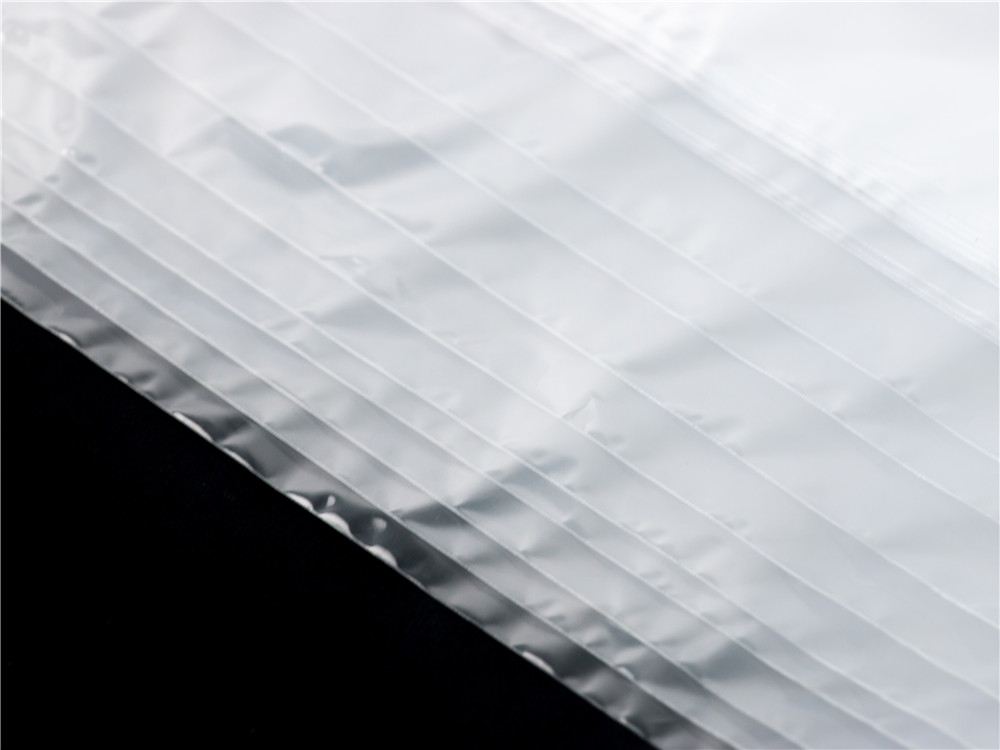

We are able to offer the service of drilling vents on the shrink film, in order to let the shrink film fit the product size evenly.

Vent size: 2mm, 3mm, 4mm, 6mm. Please confirm the vent size and the quantity of the vent line you need to our online customers service.

It is suitable for most automatic and semi-automatic packaging machines, effectively protecting products.

Shrinkage Temperature: 145-160℃

(Need to be adjusted according to different packaging machine temperature and transmission speed)

Product specification

| Thickness(μm) | Direction | 12μm | 15μm | 19μm | 23μm | 25μm | 30μm | 35μm | 40μm |

| Tensile Strength(Mpa) | Machine Direction | 140 | 135 | 130 | 125 | 120 | 120 | 115 | 110 |

| Transverse Direction | 130 | 125 | 120 | 115 | 110 | 110 | 105 | 100 | |

| Elongation Break(%) | Machine Direction | 95 | 94 | 93 | 93 | 93 | 90 | 88 | 88 |

| Transverse Direction | 93 | 93 | 92 | 91 | 90 | 88 | 88 | 86 | |

| 130℃ Shrinkage(%) | Machine Direction | 63 | 62 | 62 | 62 | 62 | 61 | 61 | 61 |

| Transverse Direction | 62 | 62 | 61 | 61 | 61 | 60 | 60 | 60 |