01

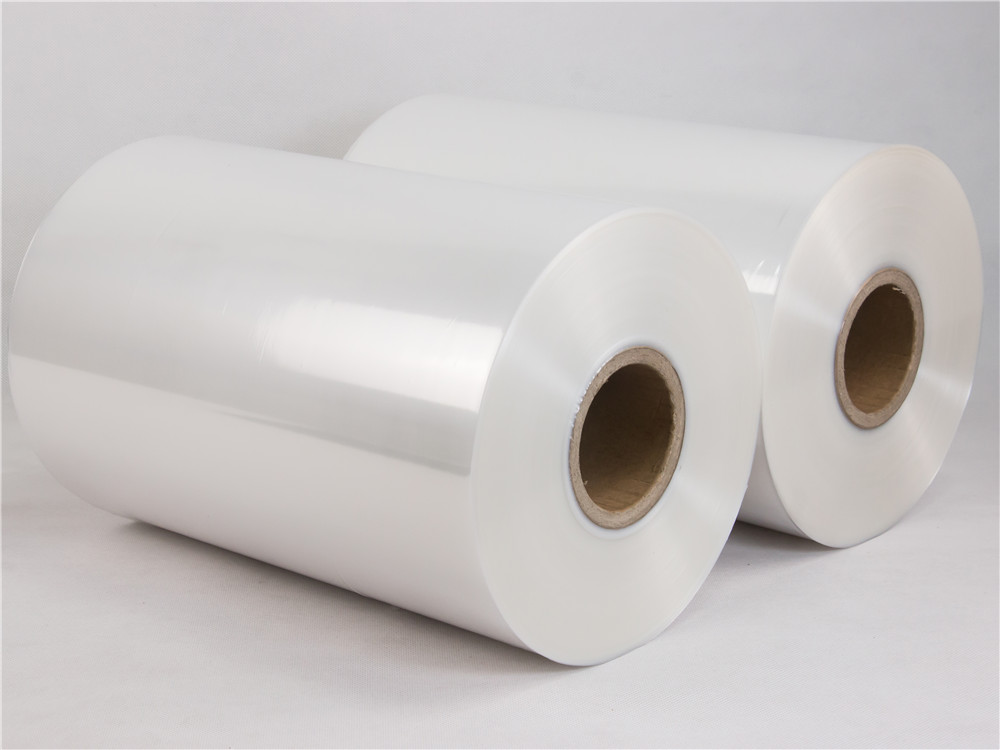

Mingca Standard POF Shrink Film for Premium Shrinkage

Product description

Standard Shrink Film is an economical and universal shrink film, which is designed to meet the general purpose of shrinking applications. Strong biaxal oriented heat shrinkable polyolefin film with stable and balanced shrinkage. It’s very effective for wrapping irregularly-shaped items and items with sharp edges or corners.

The production process of Standard Shrink Film is similar to that of High Performance Shrink Film. It’s suitable for most automatic and semi-automatic packaging machines.

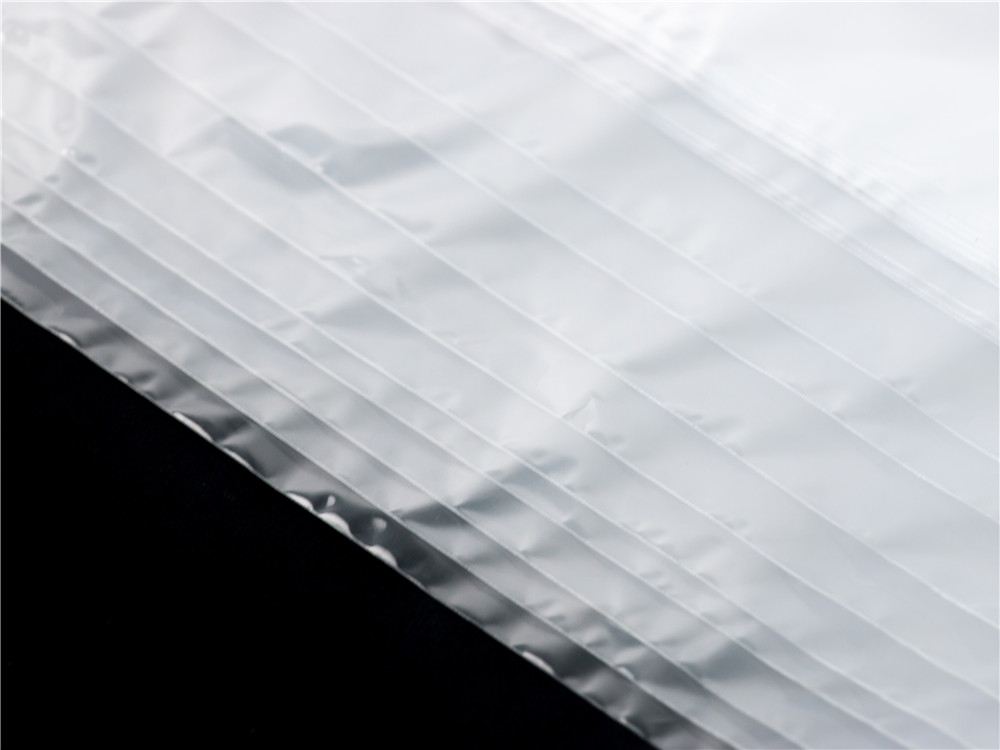

Many customers prefer POF standard shrink film because it improves the shelf life of their products. Also they are less likely to experience problems with blocking from unintended exposure to heat or sunlight.

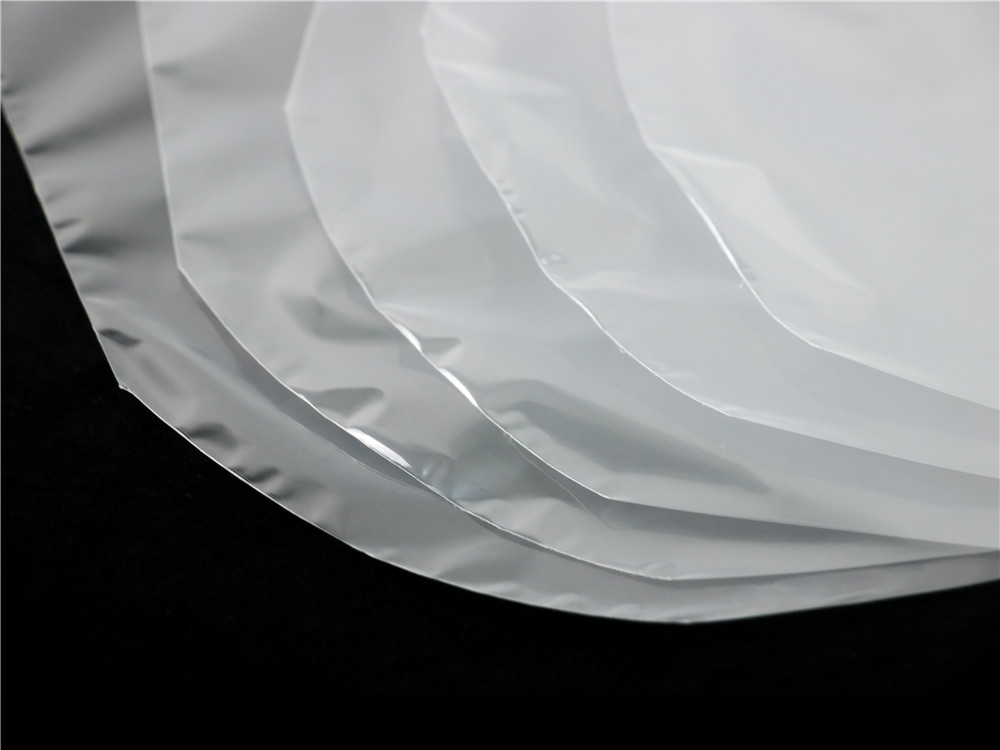

POF shrink bags are becoming more and more popular. They offer some advantages over traditional shrink bags. The main advantage they offer is the ability to come into direct contact with consumable products. Many bakeries and confectioners have waited for years for a polyolefin shrink bag to wrap consumable products in. POF shrink film has a different consistency than the traditional shrink film. It is a softer more pliable film. Because it does not contain chloride, it also puts off less odor when sealing and applying heat.

Further detail or information please check our video online or send us the email.

Shrinkage Temperature: 150-165℃

(Need to be adjusted according to different packaging machine temperature and transmission speed)

Product specification

| Thickness(μm) | Direction | 15 | 19 | 23 | 25 | 30 |

| Tensile Strength (Mpa) | Machine Direction | 130 | 127 | 125 | 122 | 120 |

| Transverse Direction | 120 | 118 | 115 | 112 | 110 | |

| Elongation Break (%) | Machine Direction | 90 | 89 | 88 | 86 | 85 |

| Transverse Direction | 90 | 90 | 90 | 88 | 88 | |

| 130℃ Shrinkage(%) | Machine Direction | 61 | 61 | 61 | 61 | 61 |

| Transverse Direction | 61 | 61 | 60 | 60 | 60 |